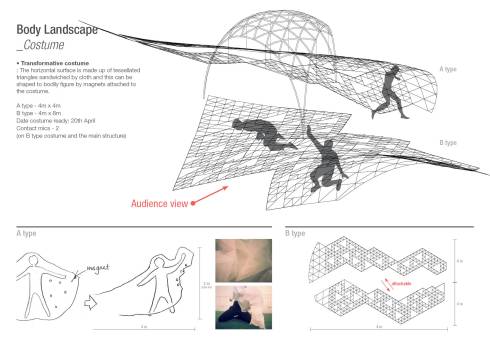

In the original plan, the transformative solid fabric can be divided into two types of costume. A-type costume is suspended to the grid shell on one side and the other side is draped down to the floor. The draped part can be formed like a body shape by fixing it with magnets and Velcro and it becomes a robe. B-type costume is a large surface of fabric lying on the floor closely located to the grid shell. This can be divided into two pieces of costume and can then be made back into one costume.

(CAD drawing: Lynette Liang Hai)

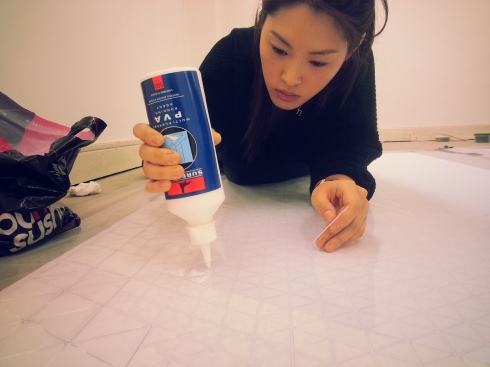

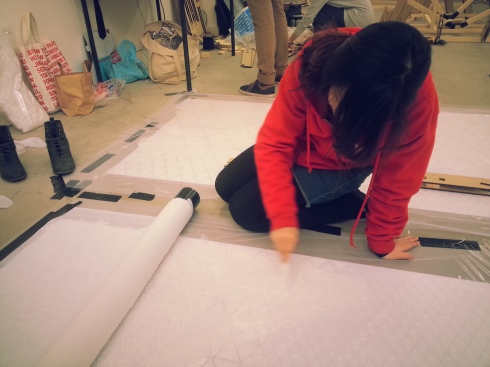

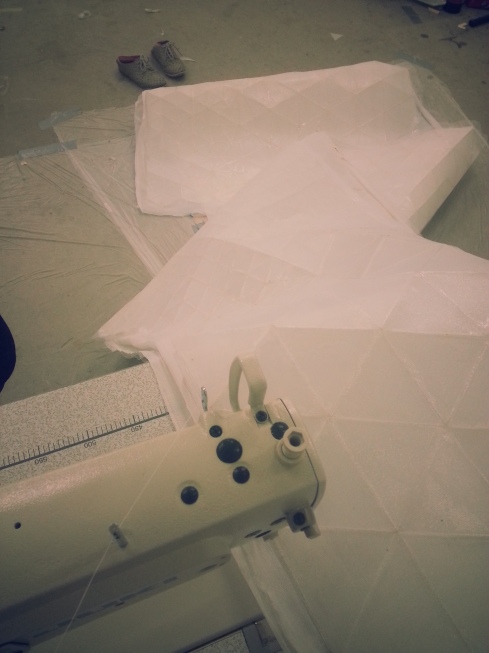

Due to the short time of production and expensive material costs, lots of things had to be planned in advance and an efficient system was required. Elyse Wong took the leading role for time management and general affairs. According to her estimate, about 30000 of triangle pieces were needed to be cut, 68 polyester sheets are needed and concluded that it needs 40 hours of laser cutting. Presuming from fabricating proto-types, I had to create an efficient system to shorten time in which other people could easily take part in to help. I printed a schematic in strips and covered them with clear film then placed bottom layer fabric. The triangle pieces were separated in different bags by sizes. People who had time could come and sit and helped gluing triangles to fabric.

Costume production Process:

– Glueing to bottom layer cloth

– Drying and removing clear film

Special thanks to Haejin Nicole Cho, Hokeon Kwak, Owen Chonos, Dong Hyune Kim, Hye Mi Chung, Khairul Ahamed, Lamia Alsudairi, Gyu Won Do.

3 comments

Comments feed for this article

September 16, 2013 at 12:07 pm

Lisboa Arquitectura Triennale: Hear the cloud | Young n the Restless

[…] Production Flow Fields in Matadero, Madrid – Cloud installation Performance with Cloud: Body Landscape, Flow Fields in […]

December 17, 2013 at 4:31 pm

carpet cleaners rug doctor

Greetings from California! I’m bored to death at work so I decided to browse your blog on my iphone during lunch break.

I enjoy the information you present here and can’t wait

to take a look when I get home. I’m surprised at how fast your

blog loaded on my mobile .. I’m not even using WIFI,

just 3G .. Anyways, wonderful site!

January 6, 2014 at 2:22 am

silidin

I’m glad that you liked my blog. Sorry for the late reply but Thank you very much for your interest! HAPPY NEW YEAR!!